Home / News / Industry News

Hot News

Hot News2026-01-20

2026-01-16

2026-01-12

2026-01-09

2026-01-04

2025-12-22

In stone projects, slab specification selection plays a critical role in structural safety, installation feasibility, visual continuity, and overall cost control.

For residential, hospitality, and commercial buildings, choosing the right slab size, thickness, and joint design is often more important than the stone pattern itself.

Proper specifications help ensure smooth construction, long-term performance, and a refined final appearance.

In international stone trade and construction practice, stone slabs are generally supplied in several standard forms.

Standard slabs are widely used for wall cladding, flooring, and countertops due to their balanced size and ease of processing.

Large-format slabs are increasingly popular in hotel lobbies, feature walls, and commercial spaces, where designers aim to reduce visible joints and enhance spatial continuity.

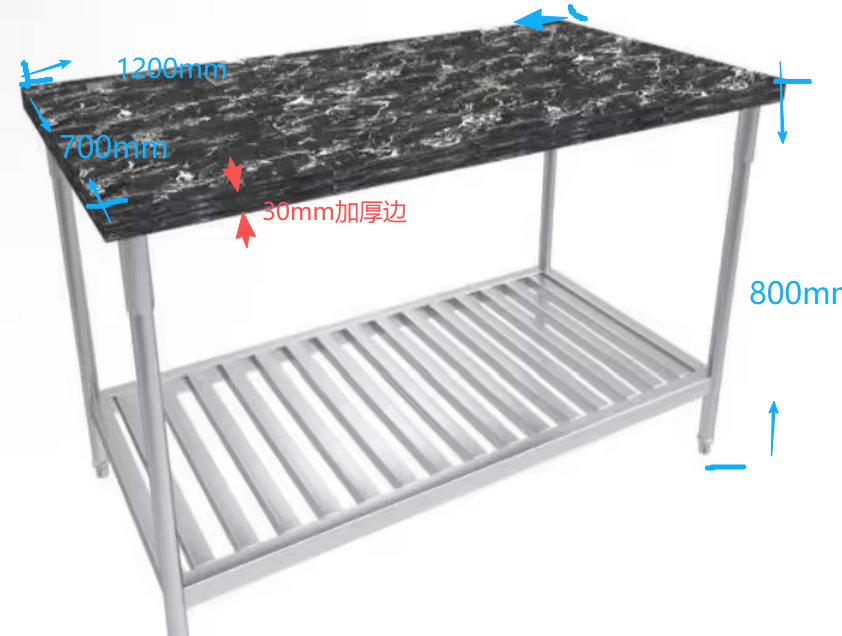

Cut-to-size pieces are processed according to shop drawings and are commonly used for countertops, vanity tops, table surfaces, and other detailed applications.

The choice between standard slabs, large slabs, and cut-to-size materials depends on project scale, installation conditions, and transportation considerations.

Stone thickness should always be determined by functional requirements and installation methods, rather than aesthetic preference alone.

A thickness of around 20 mm is commonly used for wall cladding, facades, and certain flooring applications where structural load is controlled.

A thickness of around 30 mm is widely applied for kitchen countertops, vanity tops, and table surfaces that require higher strength and durability.

In some projects, composite stone panels are used to reduce weight while maintaining surface appearance.

Regardless of thickness choice, safety, load-bearing capacity, and installation method should always be the primary considerations.

Even with large-format stone slabs, joints are unavoidable.

Well-planned joint design improves both aesthetics and long-term performance.

Key considerations include:

Planning joint locations to avoid visual focal areas

Aligning stone veins when possible for visual continuity

Allowing appropriate joint width for stone movement and installation tolerance

Prioritizing structural safety over purely visual effects

Improper joint design can lead to cracking or long-term stability issues.

Different applications require different specification priorities.

Wall cladding and facades

Focus on slab weight, anchoring systems, and long-term stability.

Flooring applications

Evaluate thickness, wear resistance, and substrate conditions.

Kitchen countertops and vanity tops

Pay attention to thickness, edge profiles, and joint reinforcement.

Large commercial spaces

Use large slabs strategically to enhance visual impact while reducing joint frequency.

Each application requires a balanced decision between design intent, safety, and practicality.

There is no universal “best” stone slab specification.

The right choice is always the result of professional judgment, based on project requirements, installation methods, and real-world experience.

Close coordination with an experienced stone supplier helps prevent potential issues and ensures stone materials perform as intended throughout the life of the project.

For project-specific slab specification support, professional consultation is always recommended.